Dieselgate: Exhaust catalysis for NOx

“Dieselgate: Technologies for exhaust after treatment" was presented by Prof. Michiel Makkee.

The presenter had a lot of technological depth and is an expert in the field of diesel emissions, including soot and NOx removal. The presentation was a lecture with substantial amount of scientic research.

Omschrijving

Dieselgate: Technologies for exhaust after treatment of both soot and NOx.

In September 2015, the US Environmental Protection Agency issued a notice of violation of the Clean Air Act to Volkswagen Group after it was found that Volkswagen had intentionally programmed vehicles to activate emissions (NOx and soot) controls only during laboratory testing. It was the start of ‘Dieselgate’.

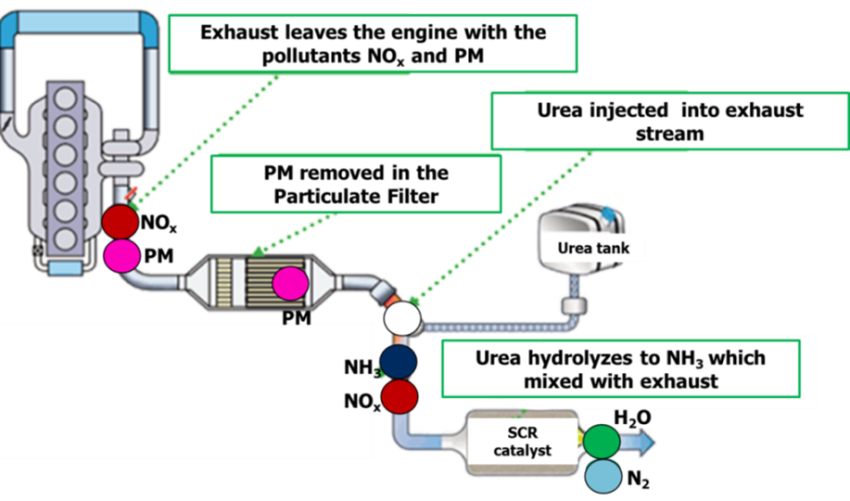

To understand Dieselgate from a technological perspective, the presenter will unveil the successful soot abatement technologies, the challenges for NOx abatement and the current discussion on NOx emission.

NOx abatement of the more fuel economic lean-burn engine remains a challenge. An updated Euro 6 and the future Euro 7 automotive legislation are anticipated to involve a further reduction of NOx emissions compared to the current Euro 6 standards. In addition, the more realistic Worldwide harmonized Light vehicles Test Procedures (WLTP) is expected to replace the outdated and un-realistic New European Driving Cycle (NEDC) of 1990. In order to comply with the anticipated Euro 7 standard, for a typical diesel exhaust composition, approximately 200 ppm NO has to be reduced to 10 ppm NO in competition with an excess of 5 % O2, 5 % CO2, and 5-10 % H2O. This means that extremely effective exhaust-emission after-treatment technologies will be required.

Presenter: Dr. ir. Michiel Makkee.

Dr.ir. Michiel Makkee (associate professor) graduated in Chemical Engineering with a specialisation in Organic Chemistry and Catalysis in 1980) and received his PhD in Organic Chemistry, Biotechnology and Catalysis (1984) both at the TU Delft. He is the inventor of the process intensification by the combination of

enzymatic conversion and heterogeneous hydrogenation in a one pot approach.

He joint Exxon Chemicals (1984) and was active in zeolite catalysis, hydro-treating, reforming, crystallisation, process evaluation, and safety.

In 1990 he was nominated as associate professor in the group of Industrial Catalysis (headed by Prof. Dr. Jacob A. Moulijn, now headed by Prof. Dr. Freek Kapteijn under the name of Catalysis Engineering).

His research can be characterised as giving solutions to some of the current challenges in society. For example diesel soot abatement technologies for which diesel engine will have mandatory closed filters in 2009 (euro 5) as well as optimal performances of FCC-operations for gasoline production. He is co-author in more than 235 international refereed papers and co-inventor in more than 25 patents.

Locatie

Prinsessegracht 23, 2514 AP Den Haag

Organisator

Olie- en Gastechnologie

Naam en contactgegevens voor informatie

Lydia Boktor