Sloshing about the boiling point

Omschrijving

Through the NOW-TTW ‘Perspective Programme’, a major public-private cooperation named Sloshing of Liquefied Natural Gas (SLING) has been established to plug the gaps in our knowledge to enable new technology for LNG tanks with crucial cost saving potential. In this presentation, the SLING project and the new facility that is being built within this project is further introduced.

The key to designing cost-effective LNG tanks is a shift to a first-principle approach to assess the dominant design loads, i.e. sloshing impacts. The state-of-the-art design method relies on sloshing model tests and requires a calibration based on operational feedback, that does not yet exist for new applications. The method is shown to be globally conservative, but does not perfectly reflect the reality. This prevents new tank designs with maximum use of the ship capacity by optimizing the tank geometry, and minimum Boil-Off-Gas by optimizing the strength of the tank.

SLING brings together an unparalleled, multidisciplinary team to draw-up the a first-principle approach to asses sloshing by disentangling the complex sloshing physics through advanced experiments and numerical simulations. The research requires a multiphase facility, that is unique worldwide and has not been developed before. It consists of a controlled environment and multiple test set-ups that are installed inside, i.e. a flume tank with a with a wave maker installed on one end of the flume and an instrumented transverse wall at the other end of the fume; a large and a small flat impactor.

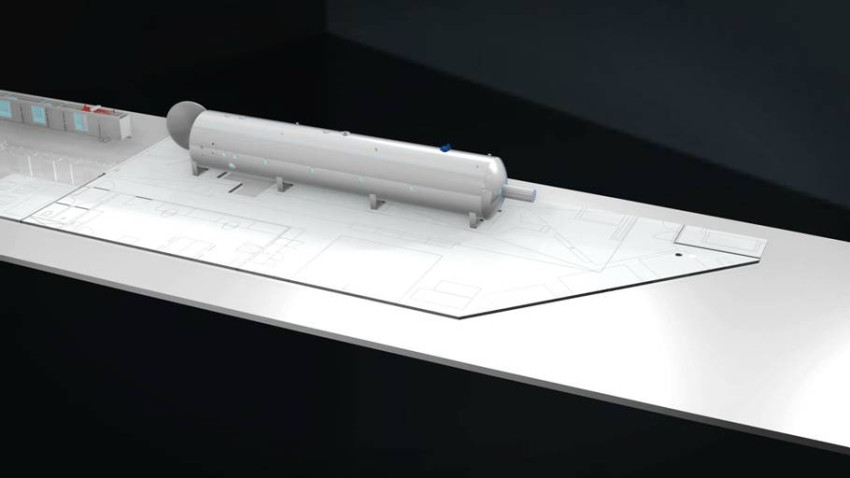

The controlled environment consists of 15 m long and 2.5 m diameter autoclave with observations windows; a gas system to supply gas; a liquid system to circulate liquids inside the flume; a heating and cooling system for the autoclave and the test set-ups - as function of the temperature in the autoclave or independently thereof - allowing for testing in the vicinity of the water-vapour boundary for a large range of temperatures (5°C to 200°C) and pressures (5 mbar to 10 bar); and a control system to automatically perform tests.

The test facility is under construction at MARIN. The first tests in the lab are expected to be performed at the beginning of 2018.

Spreker(s)

Hannes Bogaert, Head of Section Hydro-Structural Services, MARIN

Locatie

Faculty Room and Lecture Hall A - Faculty 3mE -

TU Delft, Leeghwaterstraat 17, 2628 CD Delft

Organisator

Maritieme Techniek

Naam en contactgegevens voor informatie

KIVI Martec