Motivation Georgia Skroumpelou

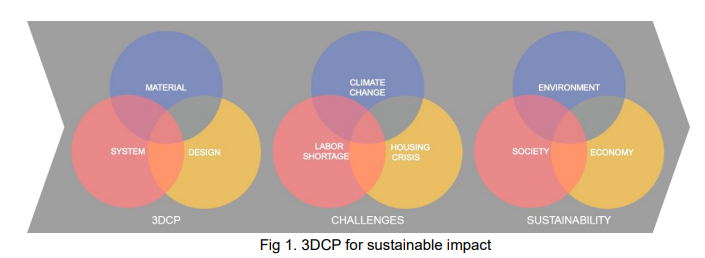

With pride and excitement I apply for the Kivi EngD Award 2025 with my project, “Additive manufacturing of functional concrete: Lightweight Mortar With Cork & Local Composition Control”. It started with a question: Can additive manufacturing of functional concrete (otherwise known as 3D Concrete Printing (3DCP)) be part of the solution for climate change, housing crisis and manual labor shortage? Through the lens of transdisciplinarity, I answered it with industrial innovations, bringing tangible impact on the transformation of construction, contributing to the solution of complex societal, environmental and economic challenges (Fig 1), receiving a final grade of 9/10.

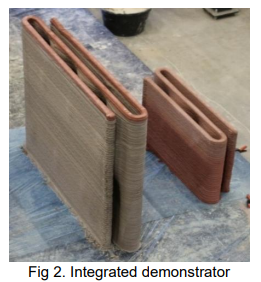

After five years in the digital construction industry, I saw the need for a holistic approach towards the implementation of 3DCP. Instead of squeezing 3DCP into existing norms, we should rethink the processes not only regarding the manufacturing methodology, but also the way of working itself; the way people, not the machines, should work for 3DCP. With this mindset, I pursued this EngD project to approach this challenge scientifically and through cross-functional collaboration. Together with two PhD researchers from TU/e, we combined structural engineering, material science, building physics, software & hardware development, systems engineering and project management to deliver, in less than 2 years, a full-scale physical demonstrator of a thermally enhanced residential wall with selectively variable material composition (Fig 2).

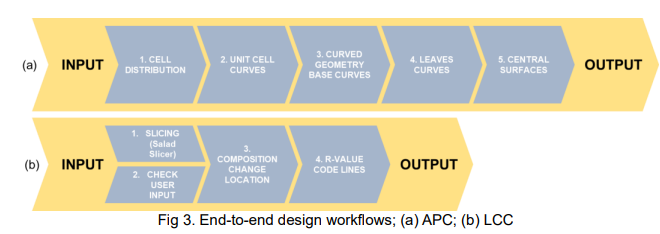

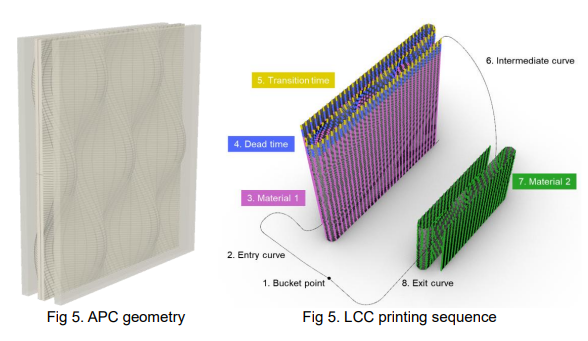

As the design engineer of this effort, I integrated academic research into end-to-end design workflows which seamlessly link design to production (Fig 3). The output of these workflows is twofold. Firstly, utilizing a newly developed mortar containing cork aggregates, I introduced a meso-scale metamaterial based on the Alternating Point Connection (APC) principle (Fig 5). This workflow populates the volume of the wall with APC unit cells, achieving 19% lower U-value compared to benchmark 3DCP walls, meeting the Dutch standards for residential thermal comfort (U ≤ 0.21 W/m²K).

This wall acts both as load-bearing and façade, simplifying the production and transportation of prefabricated 3DCP walls. Secondly, using system automations in the dosing of the printing material components, I created a parametric model which translates the design into a printable geometry with variable material properties. This process is called Local Composition Control (LCC) (Fig 5). Now mass customization can be achieved, not only through design freedom – the main merit of 3DCP up to now – but also through bespoke material variation. Such process control enables 24/7 production lines, reduces human intervention, increases safety and limits material waste.

Bringing together material (micro-), manufacturability (meso-) and design (macro-scale), these new tools are part of the transformation of the built environment, pushing the boundaries of technology, enabling the paradigm shift towards concurrent engineering and taking our society one step closer to accessible, sustainable and comfortable housing and infrastructure.

Let’s improve our world, one layer at a time.

Vote for Georgia